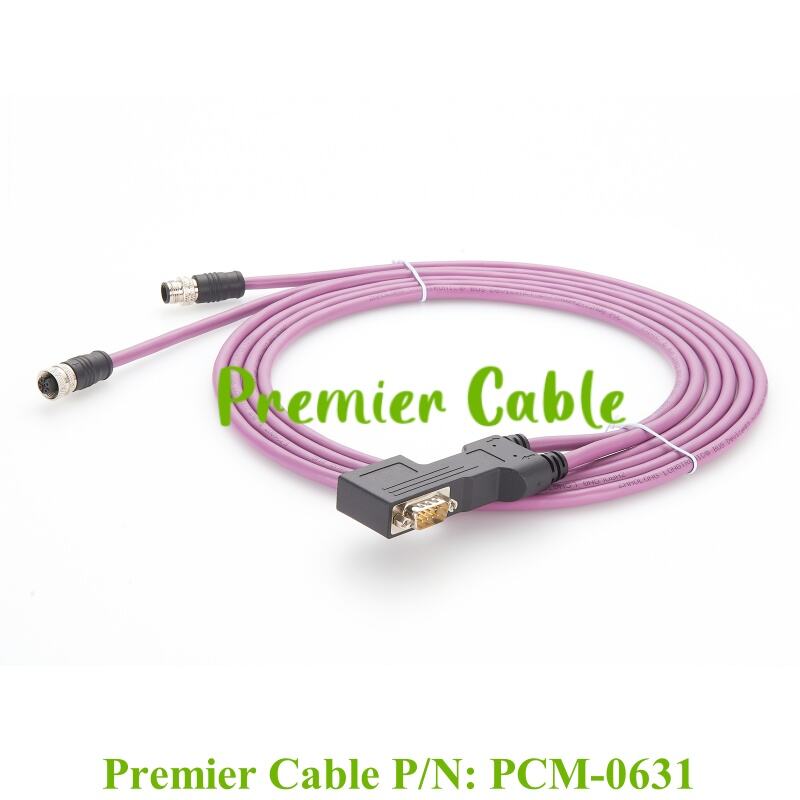

At Premier Cable we are looking forward to educating you on PLC interface cables RS232 and RS485. These cables are of prime importance as these help connect different devices in factories and other industrial premises. In this post, we will look into why these cables are important and how to select the right cable for your case, what you could do to troubleshoot certain problems and finally some things to keep in mind that helps foster a professional communication environment.

What is PLC interface cable RS232 RS485? PLC interface cable RS232 RS485, as the name implies, is a type of cable that connects different devices in a factory or industrial site. These cables are used to transmit data form one system to another. That Кабел за програмирање PLC is, for example, between a computer or programmable logic controller (PLC) and the device or sensor that must obtain this information. There are two ways of connecting: serial connections (data is sent one after the other) or parallel connections (data is sent at once). Factories commonly use these two types of communications: USART via RS232 and half duplex RS485. Just to note that in many cases, RS485 is superior than RS232 because it could be put into practice over a longer distance and with less susceptibility to noise or other interfering factors.