S7 PLC Programming Profibus Connector Cable 35 Degree is suitable for Siemens S7-300 PLC, S7-400 PLC, S7-1200 PLC, S7-1500PLC, Profibus, or MPI gateway. It can connect PLCs to Profibus networks, enabling communication and data exchange between control systems and various field devices like sensors, actuators, and HMIs. Premier Cable P/N: PCM-0636

Description

Introduction:

S7 PLC Programming Profibus Connector Cable 35 Degree is suitable for Siemens S7-300 PLC, S7-400 PLC, S7-1200 PLC, S7-1500PLC, Profibus, or MPI gateway. It can connect PLCs to Profibus networks, enabling communication and data exchange between control systems and various field devices like sensors, actuators, and HMIs. Premier Cable P/N: PCM-0636

Specification:

| Type | Profibus Cable Connector |

| Product Name | S7 PLC Programming Profibus Connector Cable 35 Degree |

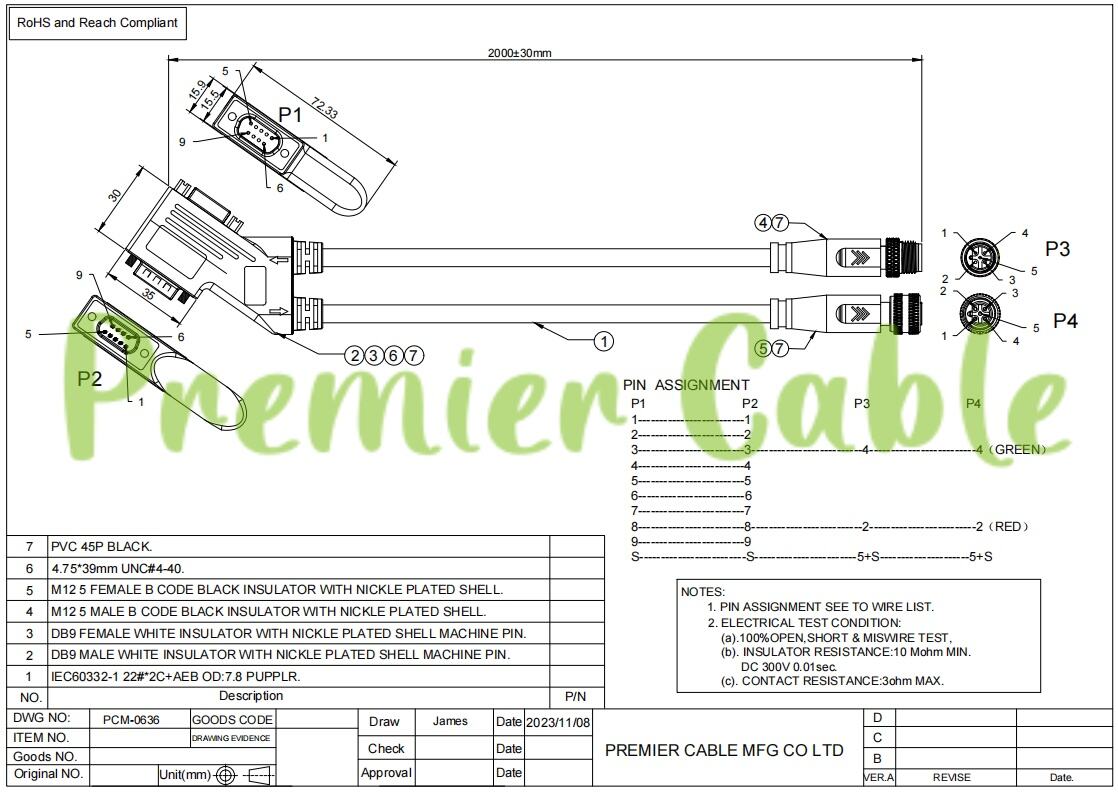

| Drawing No. | PCM-0636 |

| Connector A | DB9 Male |

| Connector B | DB9 Female |

| Connector C | M12 B Code 5 Pin Male |

| Connector D | M12 B Code 5 Pin Female |

| Cable Outlet | 35 Degree |

| Compliance | Ratings IP67 |

| Suitable PLCs | LOGO PLC, S7-200 PLC, S7-300 PLC, S7-400 PLC, S7-1200 PLC, S7-1500 PLC |

Features:

Application:

Drawing: