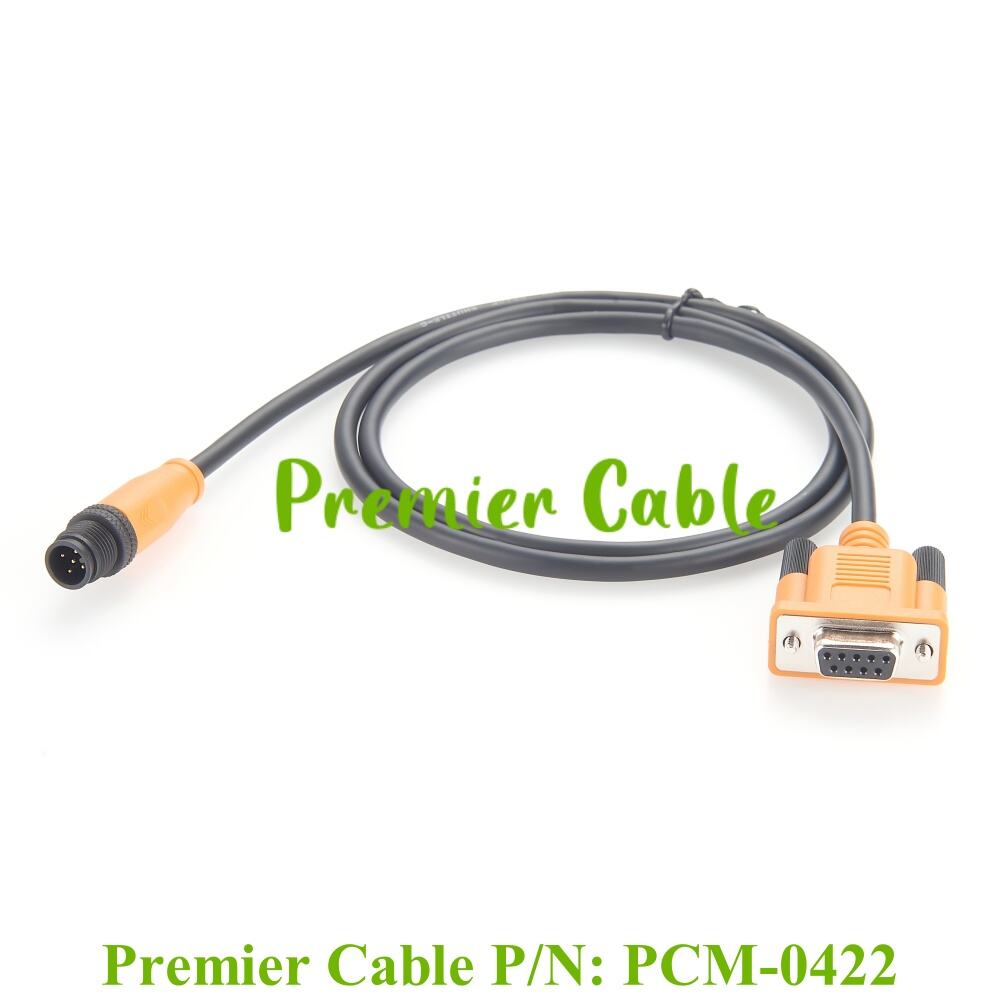

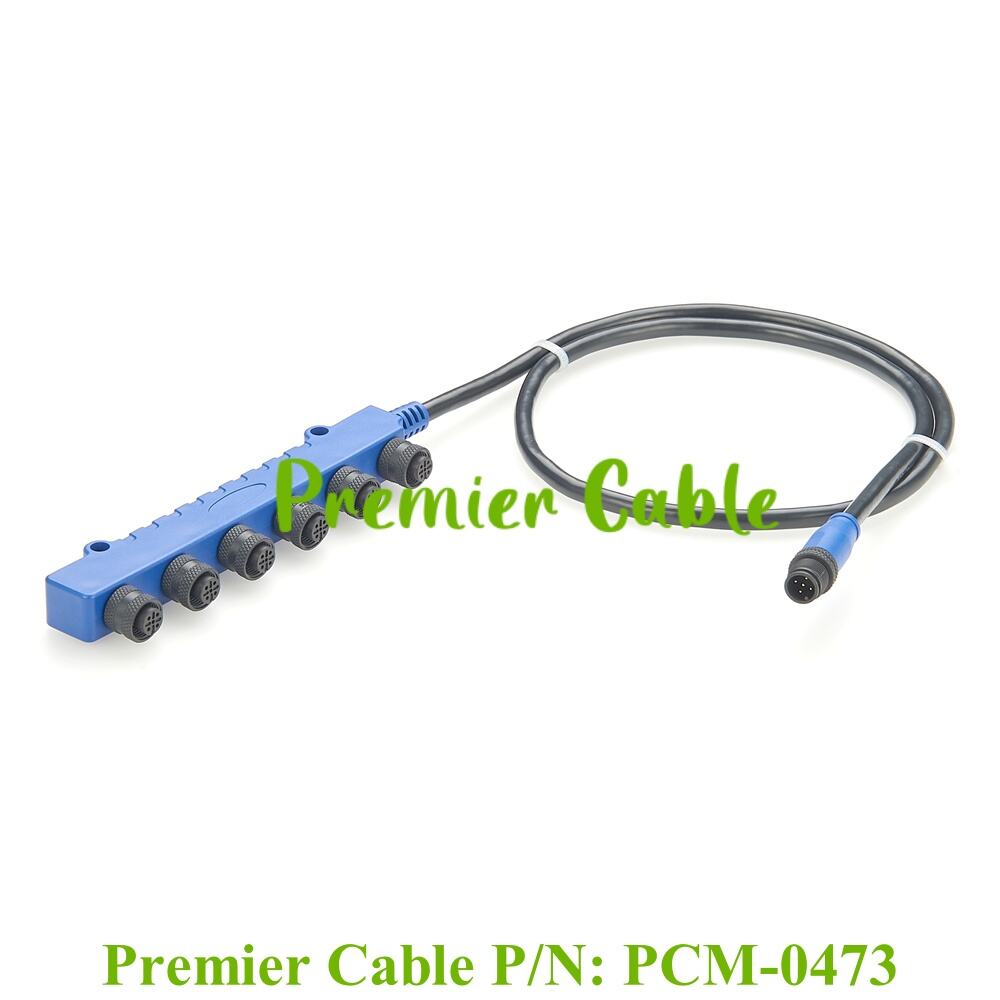

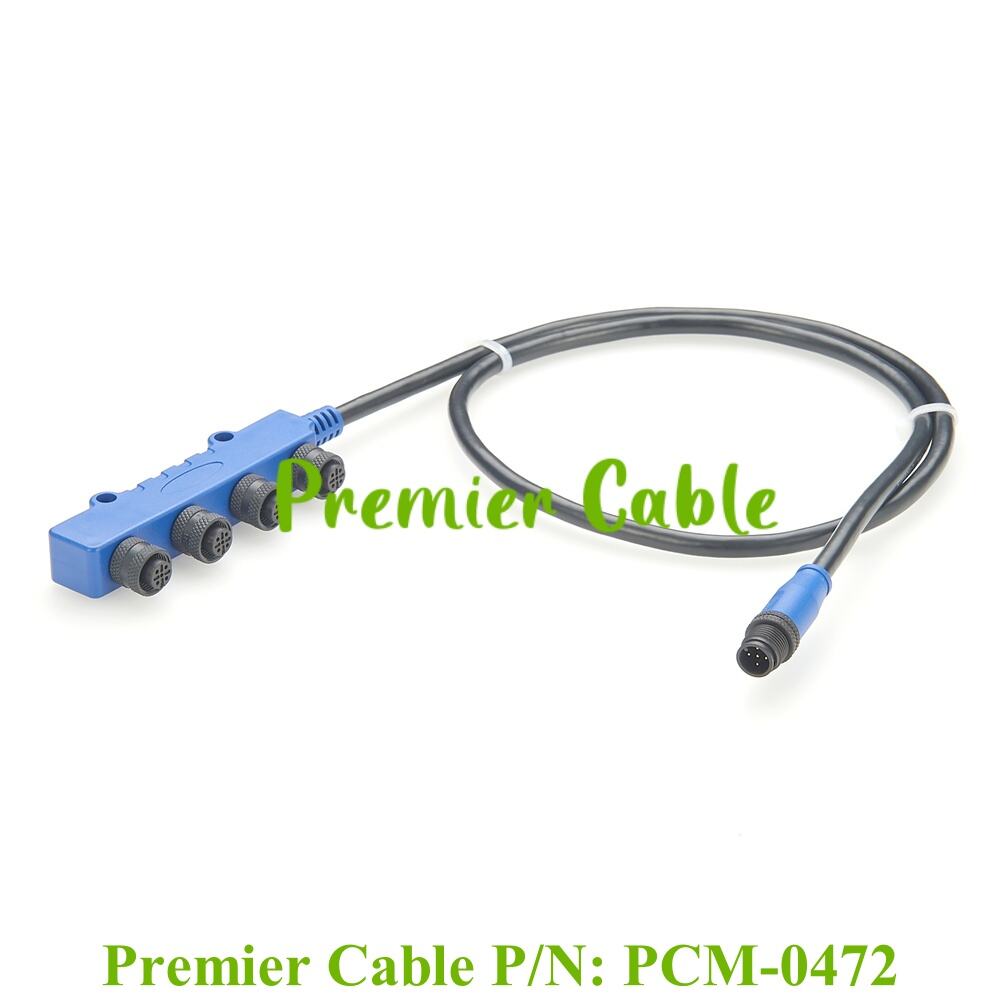

Reliable connectivity for industrial communication using M12 PROFINET Patch Cord

You might be thinking: well how does all of this connect to the larger topic of why machines should communicate with one another? Now, think about it like you are in a large factory with multiple machines working. All sorts of problems arise if the machines cannot talk to each other. As an example, imagine a contraption that is designed to clean up spills. And if that machine isn't informed that there is a spill, it will not be able to clean it up. It may not even notice the problem, and thus keep chugging along!

Or consider a machine, which helps in filling bottles with soda. Without that message stating no more bottles, it just might keep on pouring soda onto the floor! These are simplified examples and might seem a bit too funny, but when developed in an actual factory these would bring serious trouble. Hence, the information has an utmost necessity to be shared between all the devices in a secure environment. The M12 PROFINET patch cord implemented is to ensure the sending of messages can be faster and more accurate, so that each worker in factory knows exactly what he or she should do.