Do you ever wonder what large machines are working so fluently and error-free? It's really interesting! Second perhaps, only to pneumatic control systems! Such systems work on the principle of compressed air and use to control movement of various parts in machine. Their jobs assist faster and accurate operation of machines. A firm that uses pneumatic control systems is Premier Cable, for instance. Our belief is that people will work fast and accurate if they use such systems since those are a market leader in product making.

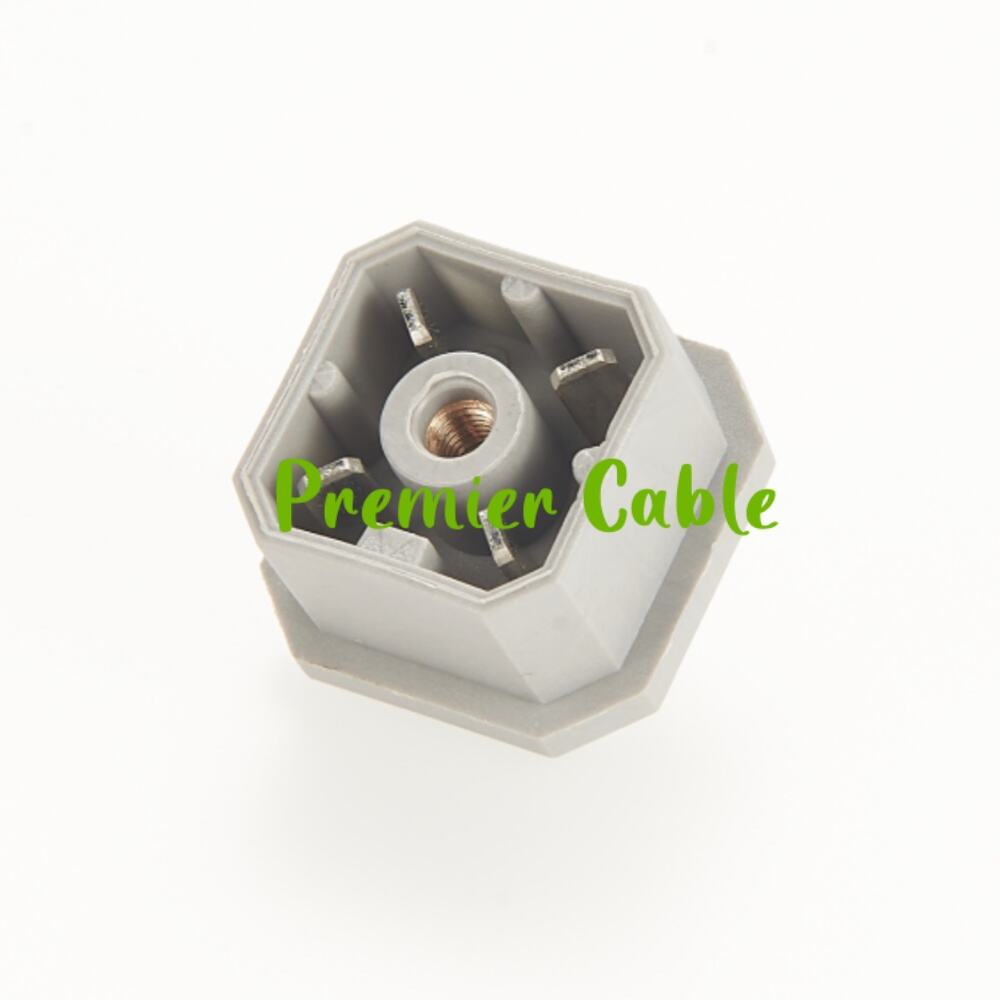

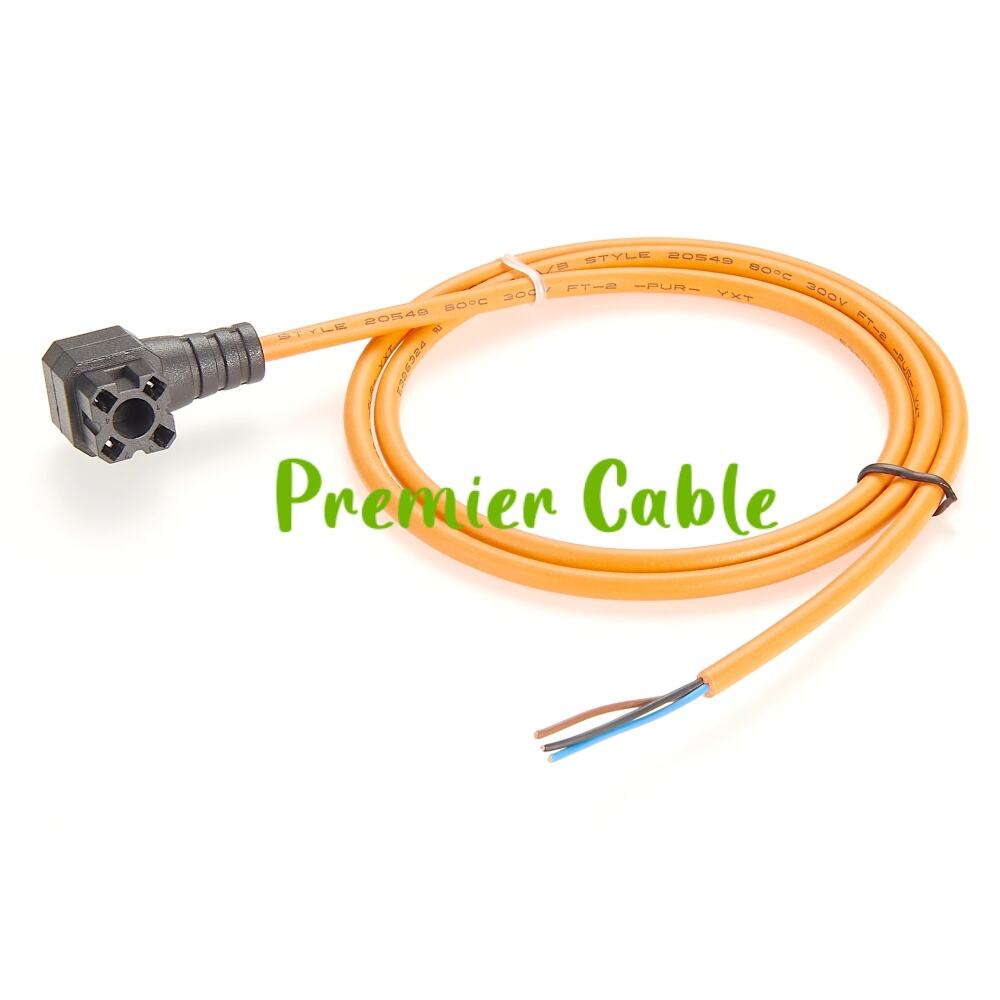

A pneumatic control system is typically a part of machines that need to be lightweight, move fast and stop on a dime. A large, complex machine is a good visual here. The actuator simply consists of a cylinder that stores compressed air and when a valve is opened, the air escapes from it. The machine is driven by a piston that moves the way the air flow. By using this system, even light weighters to move around the factory of Premier Cable without any difficultyютующуюичористему. According to him, this makes it so much easier for the workers and machines that are doing their jobs.